Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

Cell phone:13601502261

Tell:0519-88902680

Fax:0519-88903018

Address:Sheng'an Industry Zone ,Zhenglu Town ,Tianning District ,Changzhou City ,Jiangsu Province ,China.

E_mail:export@huaxiadrying.com

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Mixing & Blending >High speed Mixing & Granulation ( CE )

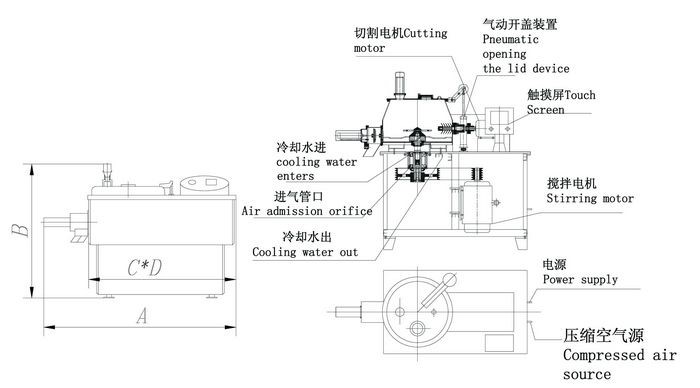

1.Descriptions

High-speed mixing granulator: high-speed mixing wet granulator is to add the main material and auxiliary materials to be granulated to the agitator in a suitable proportion and formula. The powder material and the binder are in the bottom of the cylindrical container. After the mixing paddle is fully mixed at a high speed, it is made into a wet soft material, and then cut into uniform wet particles by a side-mounted high-speed pulverizing paddle, thereby achieving the purpose of granulation. Vacuum drying and auxiliary system equipment can also be selected to achieve one-step access to the finished product directly. The biggest feature of this mixing device is fast, uniform, and no dead angle. At present, it is widely used in applications where uniformity of uniformity is required for pharmaceuticals, electronics, batteries, magnets, etc. It is gradually replacing conventional double-spiral hybrids and snails on some production lines. With mixing and double cone mixer.

2.Features

The machine adopts horizontal barrel(cone) structure. Its structure is reasonable.

The inner surface of equipment has no dead corner. It works at sealed state and conforms to the requirements of GMP.

Short granulating time, high efficiency and energy saving

The character of granule is uniform and the fluidization of granule is good. It provides ideal granule material for tablet pressing procedure.

Compare with traditional process, it can reduce 25% of binder and shorten drying time too.

Each batch needs 2 minutes to dry mixing and 1 ~ 4 minutes to granulating. Compared with traditional process, its efficiency can raise 4 ~ 5 times.

Whole operation has strict safe protective measures

3.Applications

GHL high speed mixing granulator is a high efficiency equipment that can mix different powder materials and granulate granule in one procedure. It is wide used for pharmaceutical industry, foodstuff industry and chemical industry, etc.

4.Technical Parameters

Specification |

10 |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

|

Container voiume |

L |

10 |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

Capacity |

kg/batch |

3 |

15 |

50 |

60 |

80 |

100 |

135 |

200 |

Mixing speed |

r.p.m |

300/600 |

200/400 |

180/270 |

180/270 |

180/270 |

140/220 |

106/155 |

80/120 |

Mixing power |

Kw |

1.2/2.2 |

4/5.5 |

6.5/8 |

9/11 |

9/11 |

13/16 |

18.5/22 |

22/30 |

Cutting speed |

r.p.m |

1500/300 |

|||||||

Cutting power |

Kw |

0.85/1.1 |

1.3/1.8 |

2.4/3 |

4.5/5.5 |

4.5/5.5 |

4.5/5.5 |

6.5/8 |

9/11 |

Size of installation for reference |

A(mm) |

1350 |

1650 |

1750 |

2050 |

2050 |

2200 |

2350 |

2400 |

B(mm) |

1050 |

1250 |

1300 |

1400 |

1400 |

1450 |

1450 |

1550 |

|

C×D(mm) |

1000×650 |

1250×800 |

1350×800 |

1650×850 |

1650×850 |

1700×900 |

1860×1050 |

2000×1050 |

|

男女边摸边吃奶动态图,交换朋友夫妇4中文字幕,免费午夜福利视频在线观看,久久成人国产在线,波多野结衣免费一区二区三区,亚洲精品乱码久久久久久电影,韩国片亚洲精品一区,日本最新免费在线,国产av一区二区三区毛片,国产av麻豆久久伊人